Joggling Sheet Metal - Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees.

Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees.

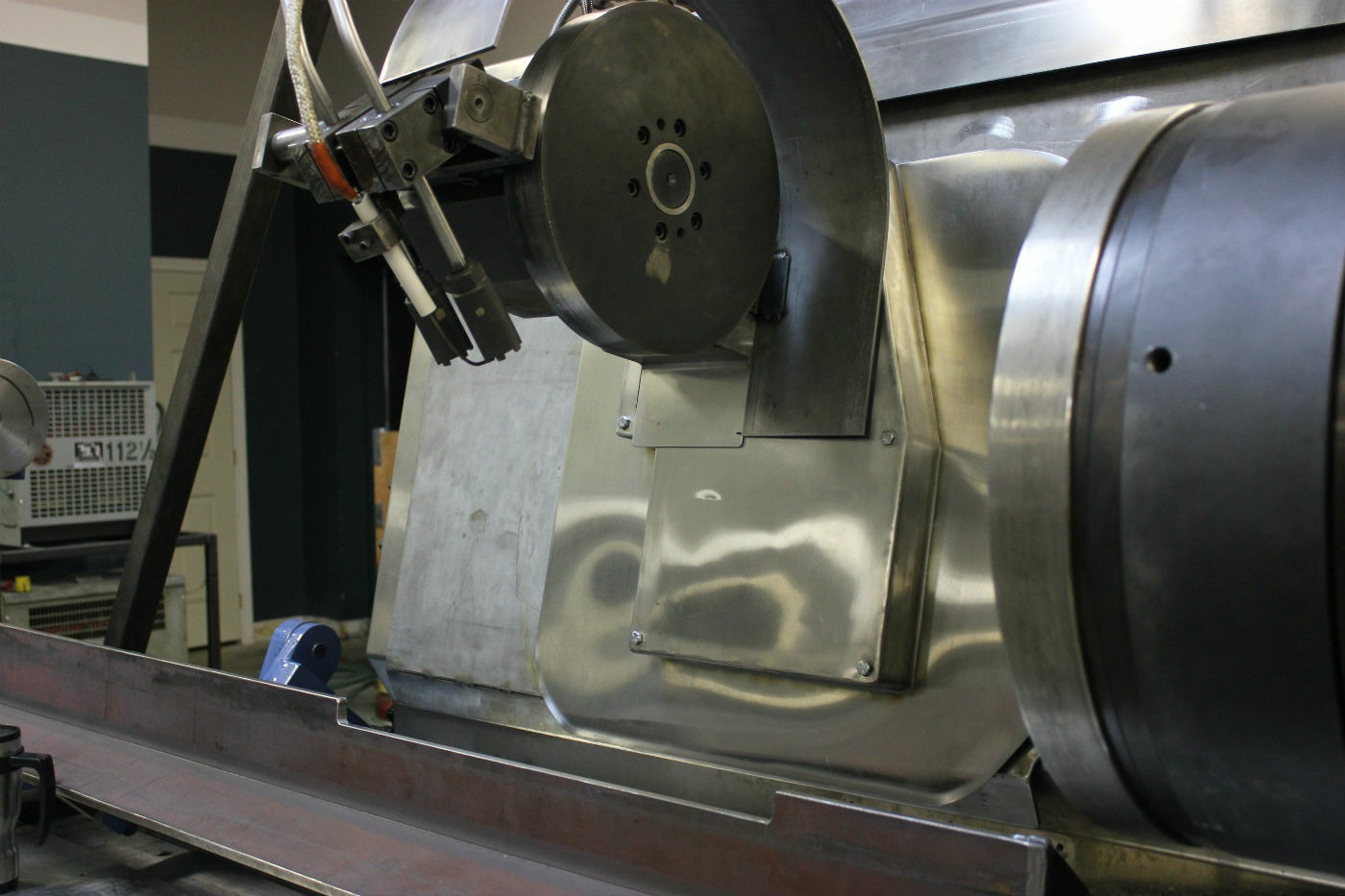

Joggle in Sheet Metal Joggling Machine for Sheet Metal

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

Joggled sheet metal brackets and their uses in UK industry

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

Folding sheet metal components with formed joggles using a CNC press

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

Joggle in Sheet Metal Joggling Machine for Sheet Metal

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area.

7 Types of Sheet Metal Bending You Should Know ECOREPRAP

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees.

Joggle in Sheet Metal Joggling Machine for Sheet Metal

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

Installing Joggle And Their Function Sheet Metal A&P YouTube

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.

What Is A Joggle In Sheet Metal

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area.

How to make a joggle in sheet metal YouTube

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees.

What is A Joggle In Sheet Metal MIHARMLE

Stretching means to lengthen or increase a particular area of metal while shrinking means to reduce an area. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without. Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees.

Stretching Means To Lengthen Or Increase A Particular Area Of Metal While Shrinking Means To Reduce An Area.

Joggle forming is a process where multiple bends are created on a sheet metal, resulting in angles less than 90 degrees. Joggling is a vital technique in sheet metal fabrication, providing a means to create strong, efficient connections without.