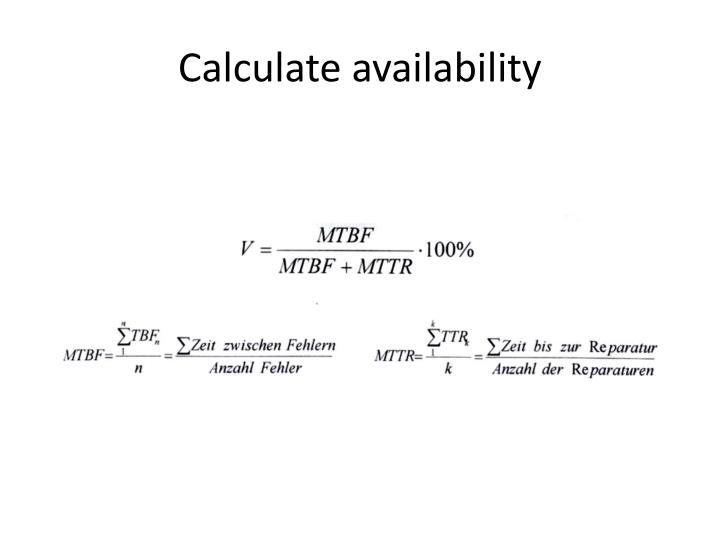

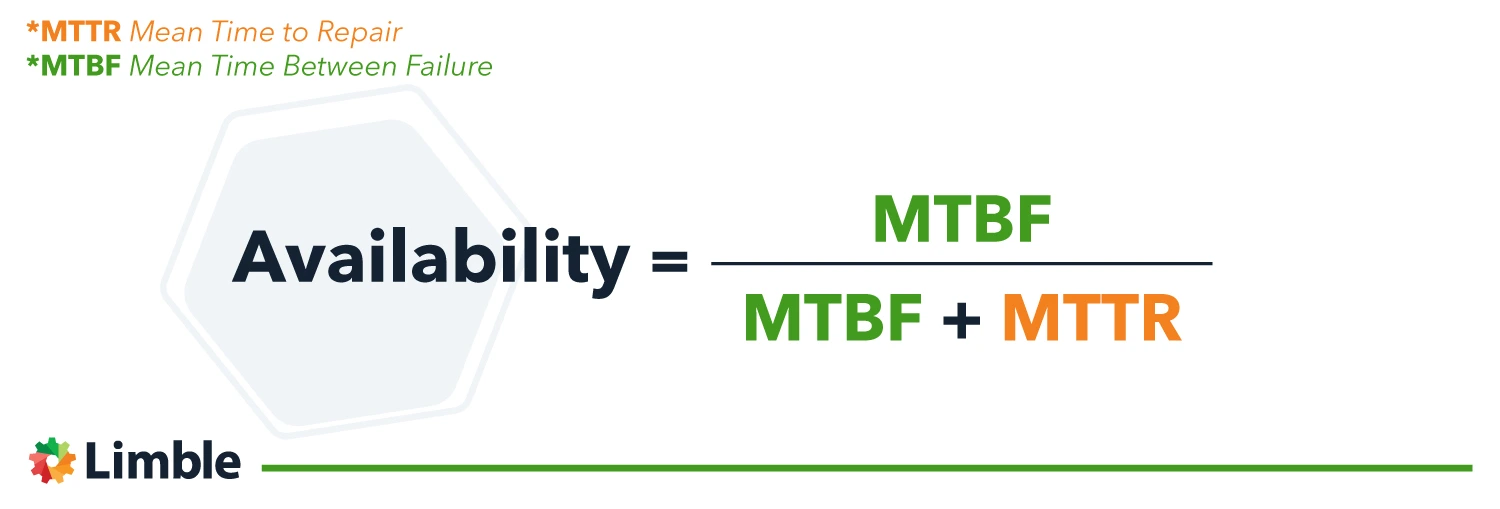

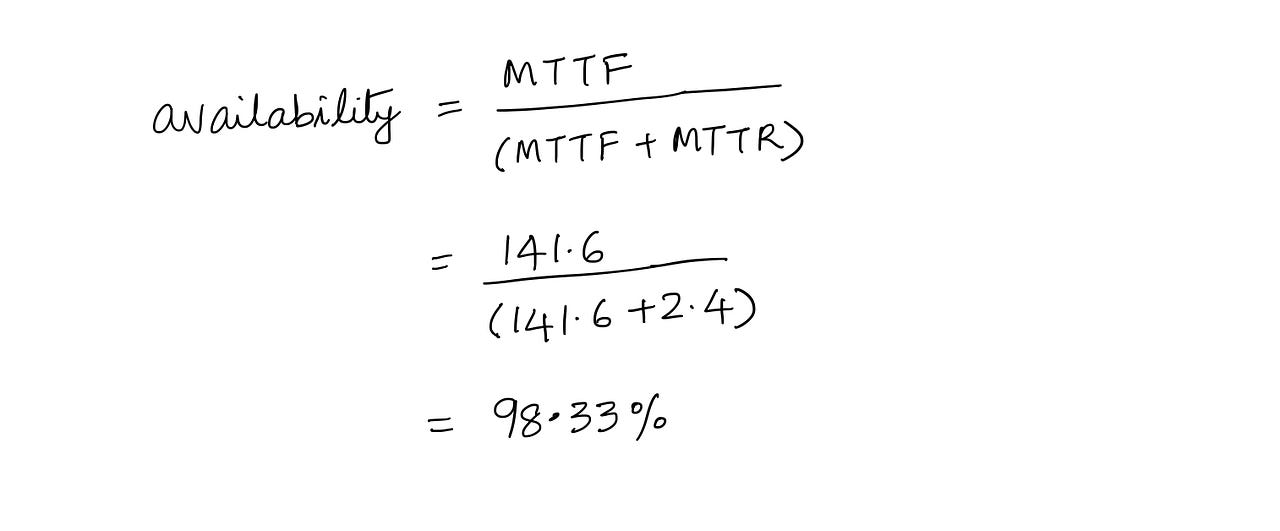

Machine Availability Formula - The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Availability = equipment uptime ÷ total scheduled time. Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability is calculated as the ratio of run time to planned production time: Availability = run time / planned production time. Machine availability is typically calculated using the following formula:

Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Machine availability is typically calculated using the following formula: Availability = run time / planned production time. Availability = equipment uptime ÷ total scheduled time. Availability is calculated as the ratio of run time to planned production time: The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and.

Availability = run time / planned production time. Availability = equipment uptime ÷ total scheduled time. Availability is calculated as the ratio of run time to planned production time: The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Machine availability is typically calculated using the following formula:

PPT Machine data collection (MDC) PowerPoint Presentation ID2621829

Availability = equipment uptime ÷ total scheduled time. Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability is calculated as the ratio of run time to planned production time: Availability = run time / planned production time. Machine availability is typically calculated using the following formula:

What Is Asset Availability And How Do You Calculate It?

Availability is calculated as the ratio of run time to planned production time: Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Machine availability is typically calculated using the following formula: Availability = equipment uptime ÷ total scheduled time. The formula for calculating machine availability is ma = mtbf / (mtbf.

How to Calculate and Improve Machine Availability

Availability is calculated as the ratio of run time to planned production time: Availability = equipment uptime ÷ total scheduled time. Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Machine availability is typically calculated using the following formula: Availability = run time / planned production time.

How to Make an OEE Calculation HubPages

The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Machine availability is typically calculated using the following formula: Availability = run time / planned production time. Availability is calculated as the ratio of run time to planned production time: Availability = equipment uptime ÷ total scheduled.

Illustration of the estimation of machine availability Download

Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability = equipment uptime ÷ total scheduled time. Availability = run time / planned production time. The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Machine availability is.

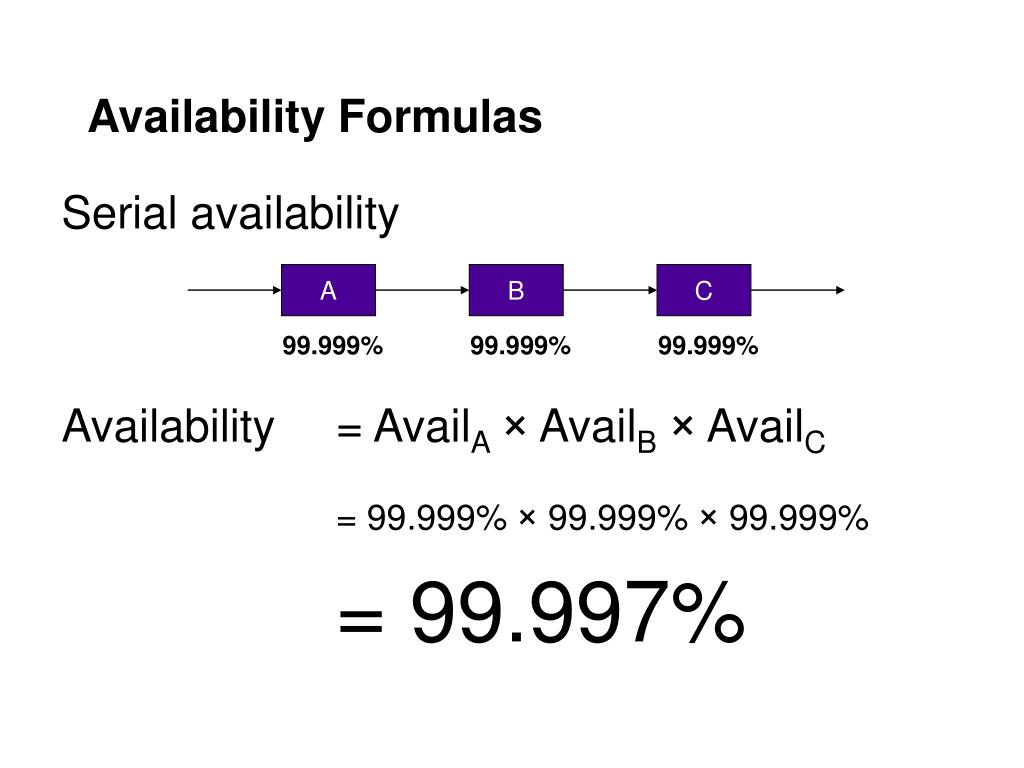

Measuring Service Availability. Availability is the actual time your

Availability = run time / planned production time. Availability is calculated as the ratio of run time to planned production time: Machine availability is typically calculated using the following formula: Availability = equipment uptime ÷ total scheduled time. The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures.

How to Calculate and Improve Machine Availability

Machine availability is typically calculated using the following formula: The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Availability is calculated as the ratio of run time to planned production time: Availability = equipment uptime ÷ total scheduled time. Understand the machine availability metric in supply.

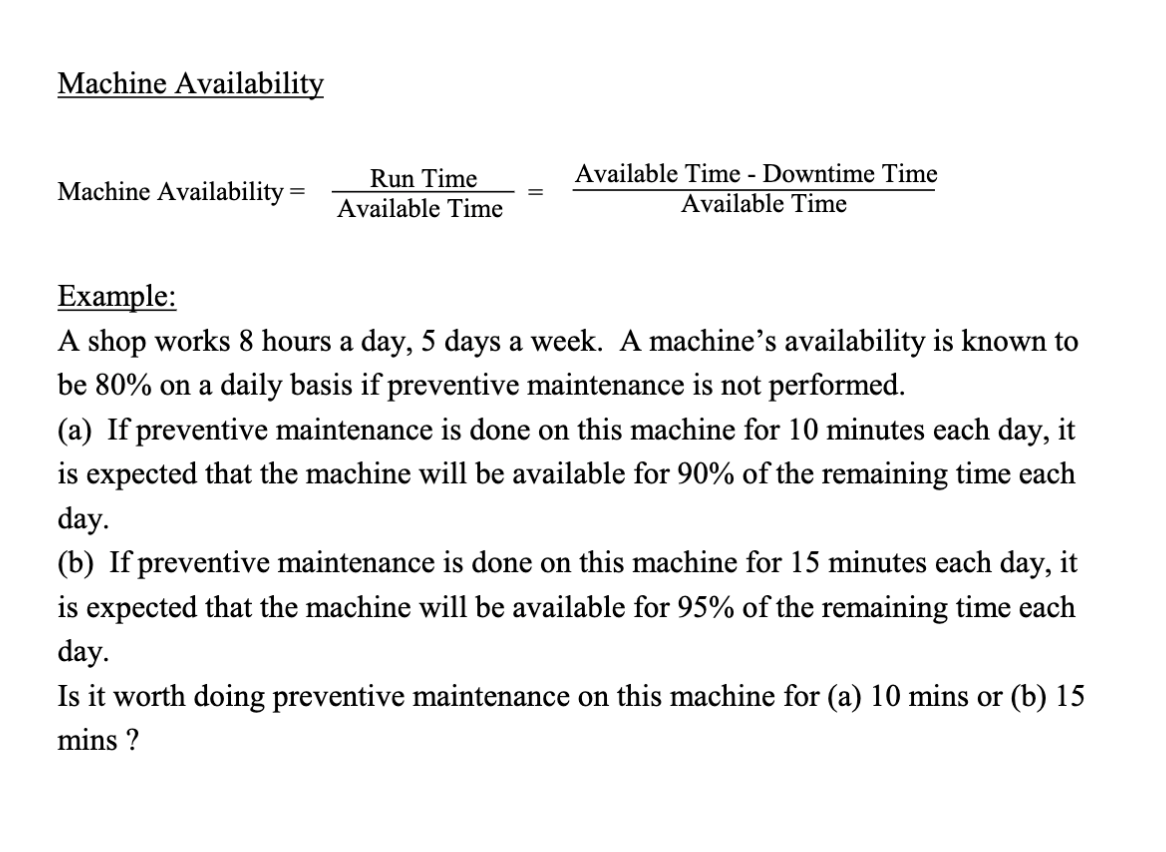

Solved Machine Availability Machine Availability Run Time

The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability = equipment uptime ÷ total scheduled time. Machine availability is typically calculated using the following formula: Availability is.

PPT High Availability Design Ram Dantu PowerPoint Presentation, free

Availability = equipment uptime ÷ total scheduled time. Machine availability is typically calculated using the following formula: Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability = run time / planned production time. Availability is calculated as the ratio of run time to planned production time:

Improve machine availability with moneo ifm

Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Machine availability is typically calculated using the following formula: Availability = run time / planned production time. The formula for calculating machine availability is ma = mtbf / (mtbf + mttr), where mtbf is the mean time between failures and. Availability =.

Machine Availability Is Typically Calculated Using The Following Formula:

Availability is calculated as the ratio of run time to planned production time: Understand the machine availability metric in supply chain — its purpose, calculation, ideal trend, recommended frequency, and associate. Availability = equipment uptime ÷ total scheduled time. Availability = run time / planned production time.